Particle size reduction through hammer milling is used to improve powder properties so that the material has improved flow ability, reactivity, bulk density and compatibility.

Using high speed rotating blades to crush or grind raw materials to a desired size which is smaller than the perforated plate screen.

Blades can be knife-edged for gentle granulation or blunt-edged for more impact and aggressive particle size reduction. A blade with reversible edges becomes truly versatile, being able to match any product requirement.

Air seal design to prevent powder enters to main shaft.

Various screen's sizes and types (e.g. square, round, etc.) according to customer's request.

Parts can be easily disassembled for cleaning and maintenance.

TECHNICAL SPECIFICAITONS:

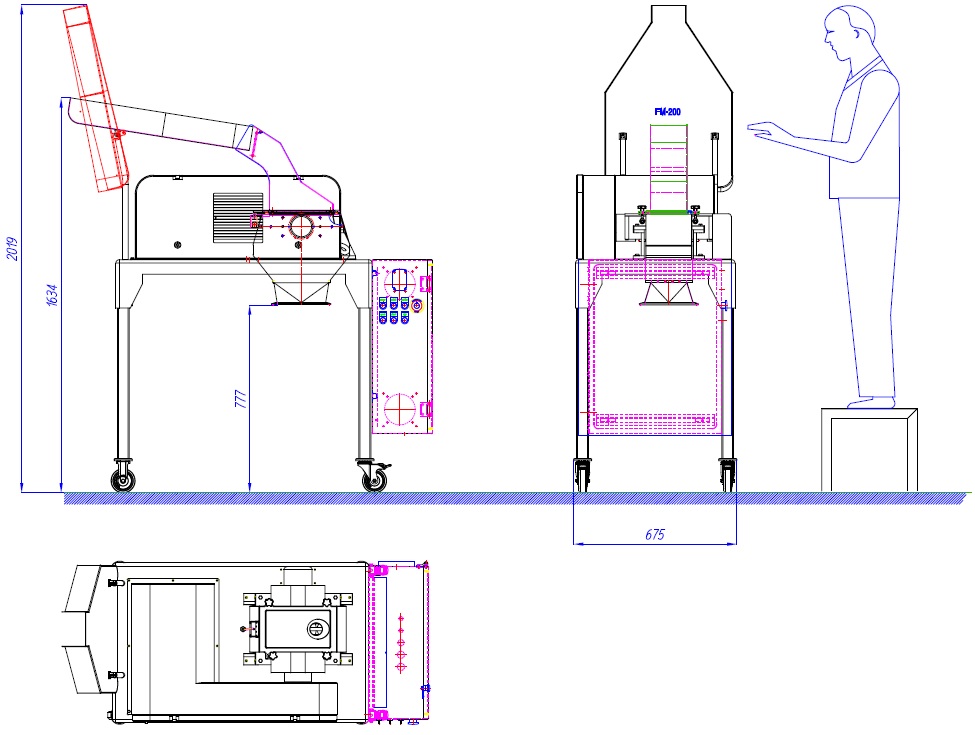

MACHINE LAYOUT: