STV Fluid Bed Dryer, Granulator & Coater with advanced design and innovative technology brings the optimum solution for drying and granulating in pharmaceutical industry.

It allows you to dry, granulate and coat more efficiently with one and the same product container. With an ideal air distribution and an efficient filter system, you can achieve maximum drying efficiency at minimum product losses. Heat transfer and drying are more homogenous and faster, with a high flexibility in batch size.

Through the uniform fluidization and the nozzles positioned in the bottom, a perfect liquid distribution is obtained, creating granules with a unimodal particle size distribution. The same set-up can be used for pellet and particle coating resulting in much faster and more homogenous layering.

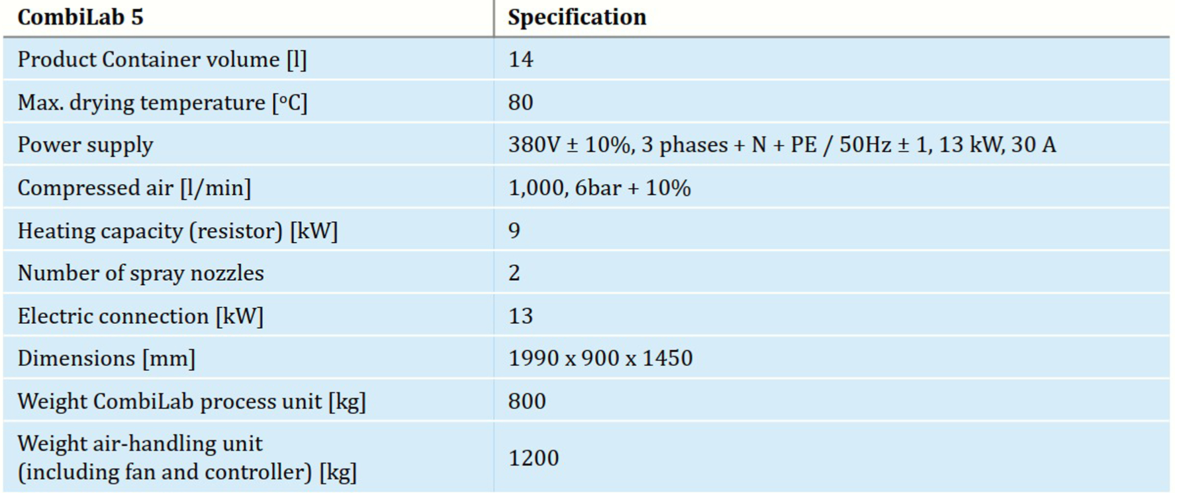

For batches from 2 kg up to 5 kg

For drying, granulation and coating and with certain limitations for organic processes

Bottom spray system

Bottom plate 45 degree

Flow meter

Processes:

Process unit with separate air handling unit which is installed in the technical room.

TECHNICAL SPECIFICAITONS:

Our well-established Fluid Bed Dryer, Granulator & Coater SDGC, for granulation of solids in the tangential spray process with uniform, consistent quality.

High process efficiency due to extremely fast drying with gentle product handling. For batch sizes from 20 to 500 kg/batch. Other batch sizes on request.

State of the art drying technology: Inclined cutting of container bottom plate to create turbulence airflow which makes granules dry quickly. As a result, drying process is more effective.

Tangential is the latest technology in fluid bed granulation which can cut off by 50%-75% process time compared to traditional technology (Top spray and bottom spray), giving the highest operation efficiency.

Depending on customer needs, the machine is designed as 2 bars or 10 bars pressure resistant.

WIP (Wash-In- Place) system can be integrated on the machine or through a mobile washing station.

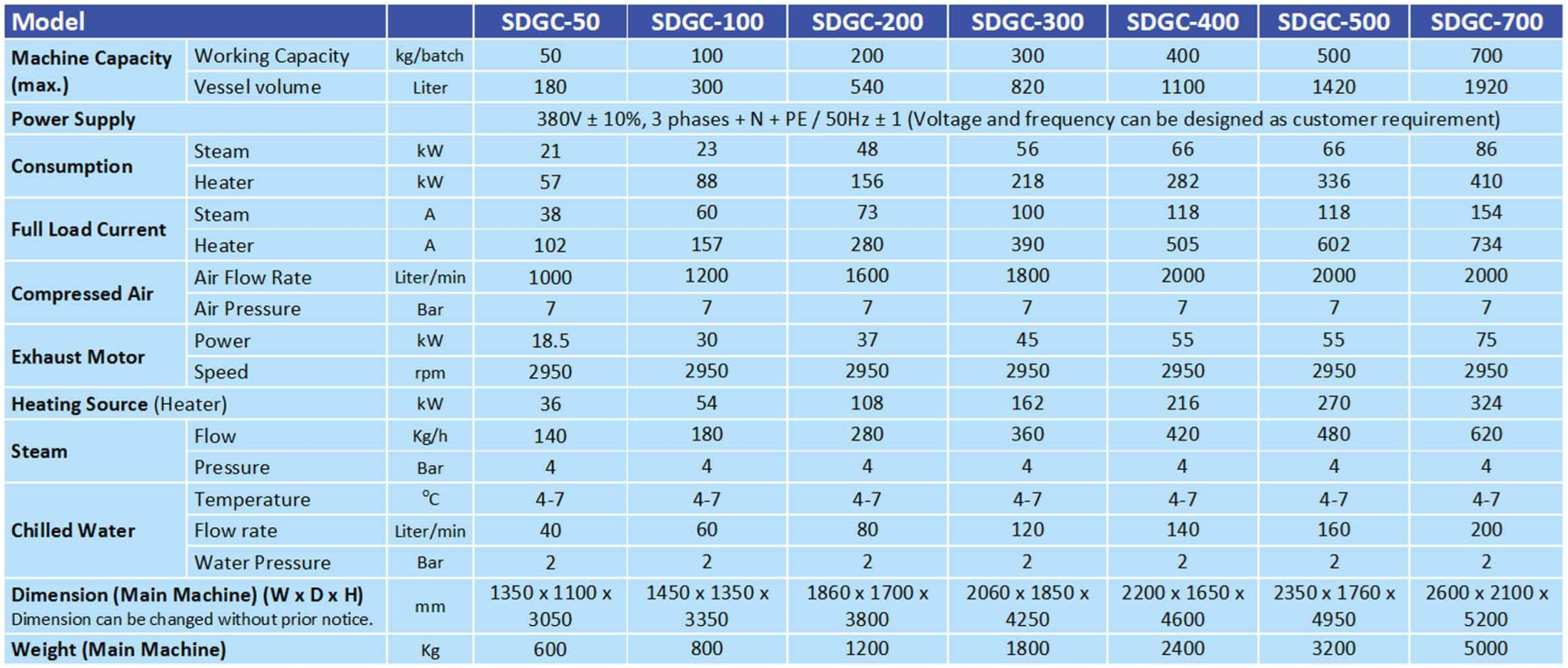

TECHNICAL SPECIFICAITONS: