High Shear Mixer & Granulator is ideal equipment to mix and granulate from wet powder mass. The equipment is used widely in pharmaceuticals and foodstuff industry. Equipment intended to be used for following purposes:

The intelligent design makes it possible to achieve complete circulation of the material to be mixed even at low speed. Further advantages lie in the effective surfaces of the chopper, which, due to their positioning, allow optimal compaction of granulates and targeted control of the grain spectrum and thus also optimally mix and granulate products with a lower flow ability.

Of course, safety is always an important criterion in all production processes, especially when using highly flammable solids or organic solvents. Reliable explosion protection is essential here. For this purpose, we have developed protective procedures, for example, inerting with nitrogen as well as explosion pressure shock resistant construction. In our measures, we pay strict attention to meeting international requirements. With our granulation systems, you get high-quality, high-performance machines that are as efficient as they are safe and can be operated intuitively.

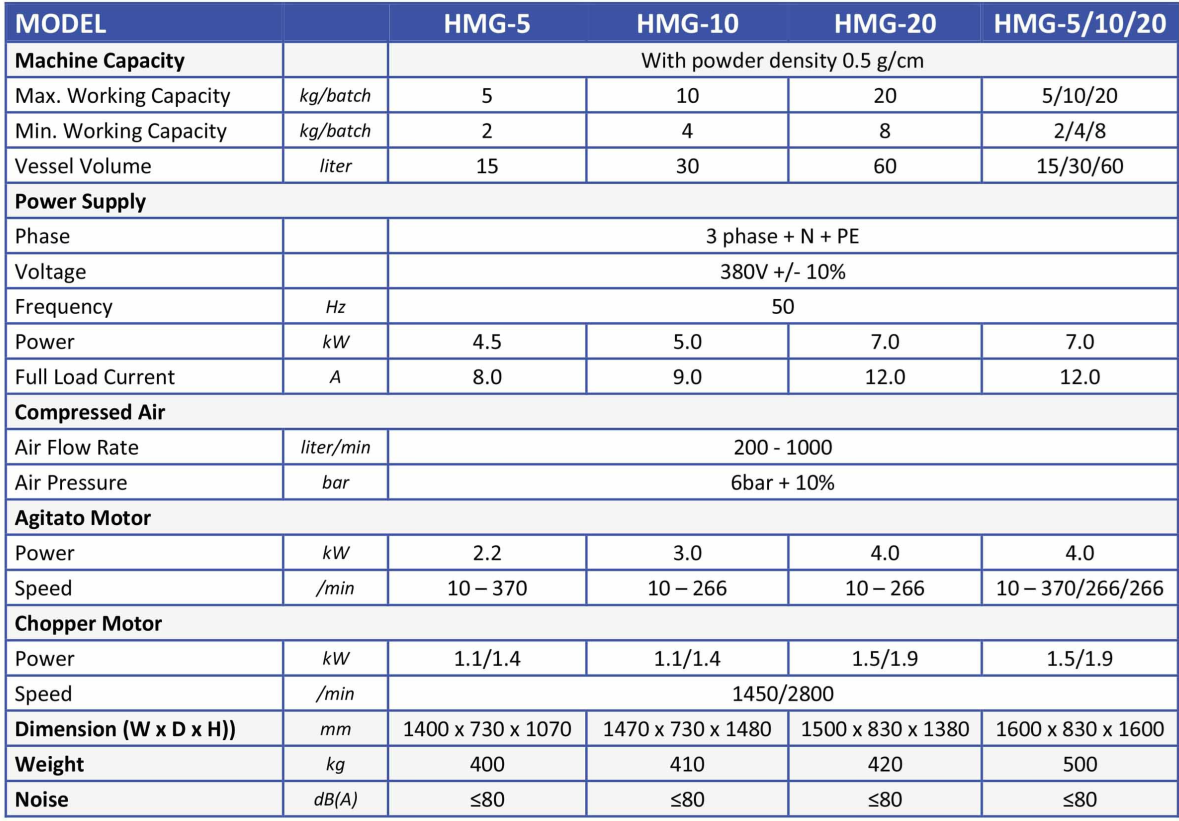

Our laboratory mixers HMG-5/10/20 were developed as flexible laboratory machines with interchangeable design. Different bowls can be added at a later time.

A scale-up can be carried out without much time and effort.

The HMG laboratory system ensures that the respective process units can be changed quickly. All mobile units can be docked and undocked by one person without tools.

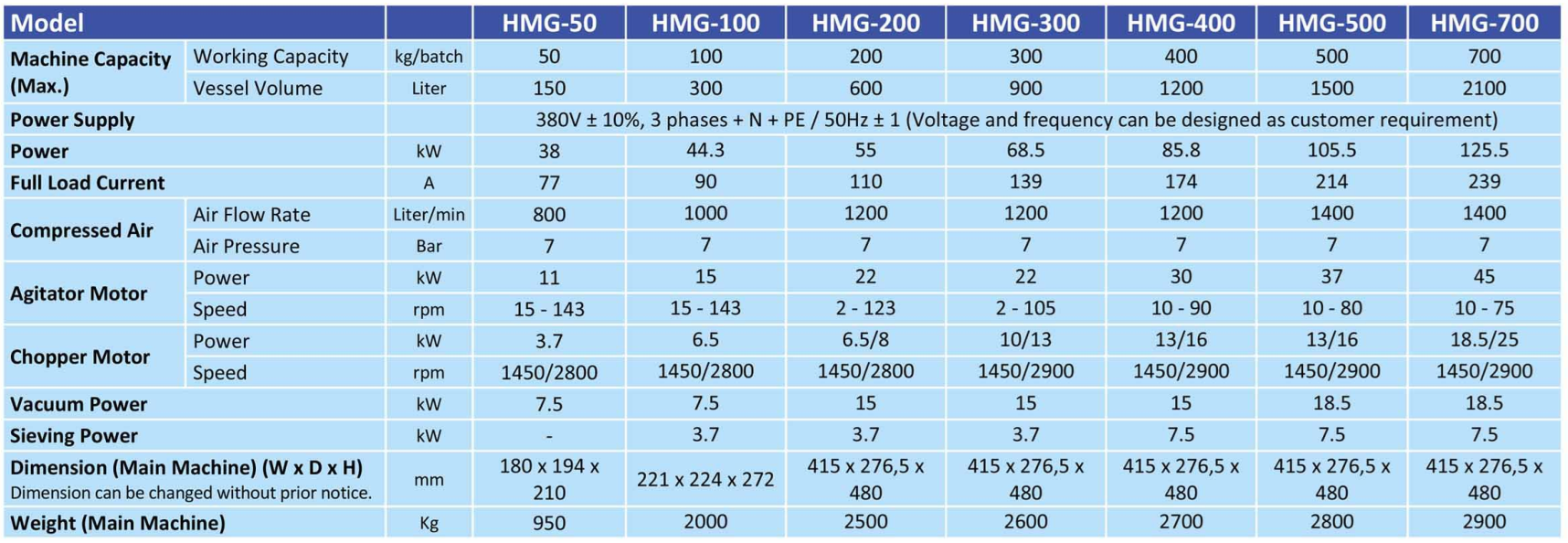

TECHNICAL SPECIFICAITONS:

We offer the pharmaceutical mixers 50-500 kg as granulation systems with a high capacity. These are machines with permanently installed mixing vessels, which optionally have a pressure resistance of 12 bars.

The compact and user-friendly design ensures economical production processes.

High Shear Mixer & Granulator is designed for mixing and granulating from wet powder mass with liquid excipient, it is used for production lines in pharmaceutical, food industry and other related industries. Its state-of-the-art design allows for the efficient mixing and granulation of powders. The special design of the bowl and impeller geometry provides the user a flexible method to produce dense granulations with exceptional properties. Additional operational features incorporated into the design provide for fast and complete cleaning.

Within a few minutes a homogeneous distribution of the product is reached. After the addition of the liquid binder the powder particles form granulates cores. A horizontal rotating chopper breaks lumps and agglomerations.

Highlights:

TECHNICAL SPECIFICAITONS: