To homogenize the particle size, whether the characteristic of the powder or granule is normal or sensitive to temperature, humidity,… powder containing sugar or not, we always have the optimal solution for all applications. Explore our advanced Milling / Sieving technologies to find the right solution for your process.

3 in 1 Freedrive Sieving, Sizing and Milling is an excellent solution for reducing particle's size in the pharmaceutical, food industry and fine chemicals. This model integrates its base and controls into a self – contained unit and is supported with wheels to ensure the mobility.

Particles benefit from down – driven design to flow vertically and smoothly throughout milling house.

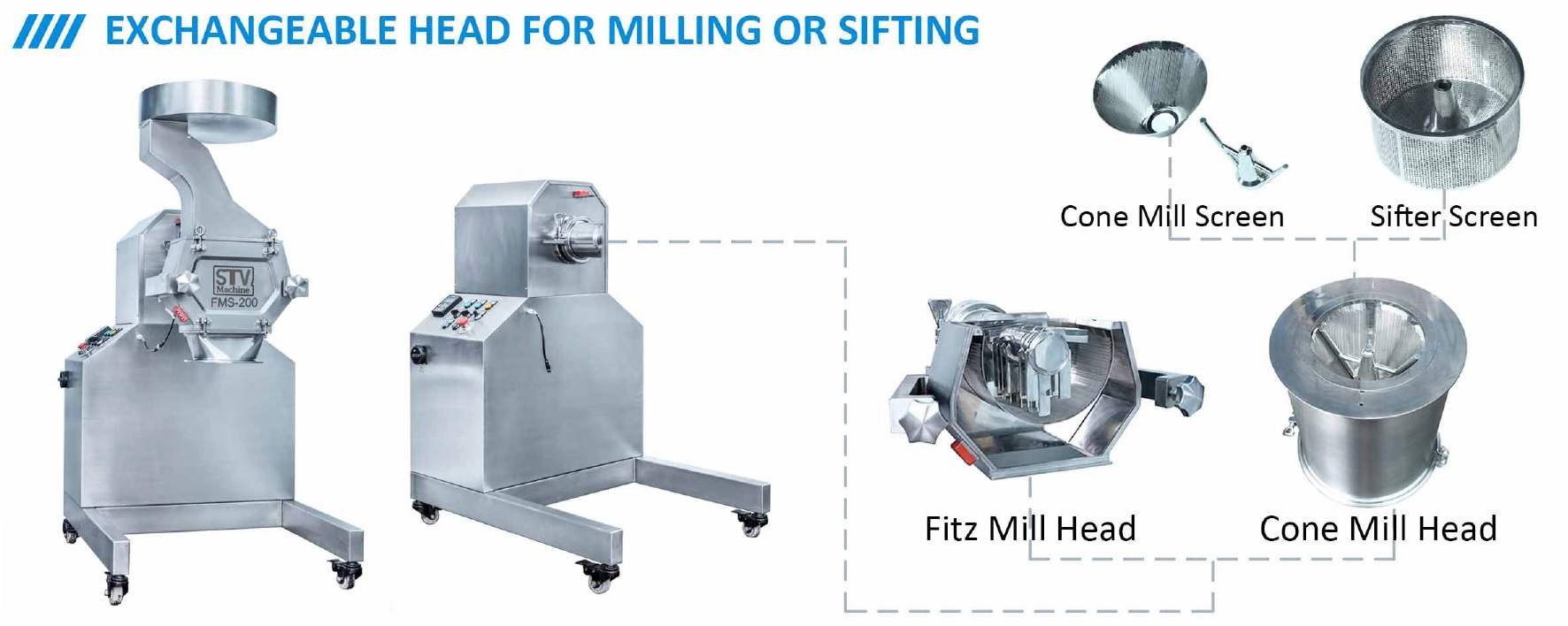

Its design can be exchangeable between Fitz Mill Head and Sifter Head.

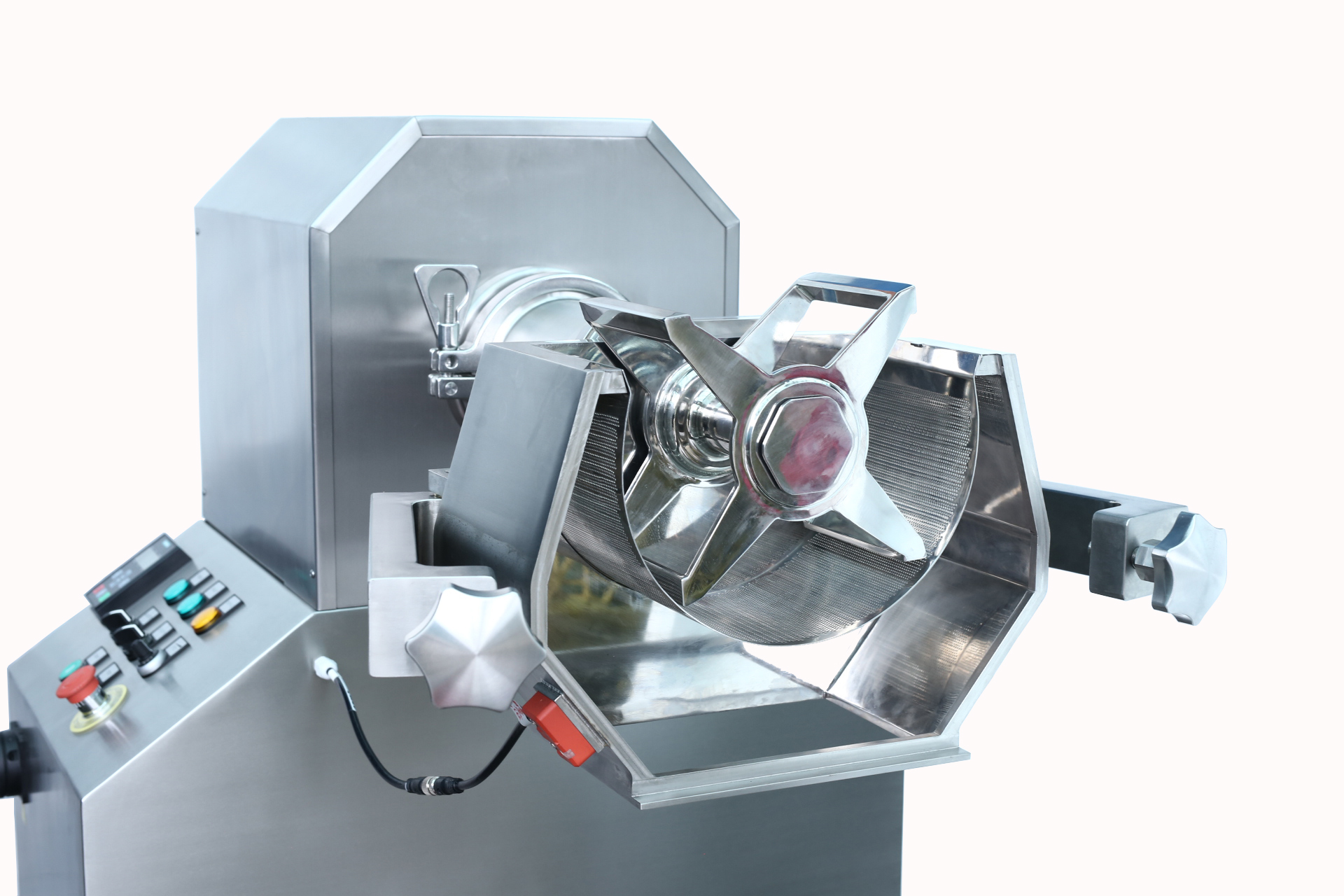

The standard blade rotor can be reversed working direction (blade side or back side). Operator can also flexibly replace it with a bar rotor in order to granulate and delump more gently (no mechanical contact between screen and rotor).

Various screen's sizes and types (e.g. square, round, etc.) according to customer's request.

Main motor is prevented from air dust by an air seal attached to the milling house.

To suit factories with many product lines that need many different technologies, instead of investing in many machines with each machine for each technology, we have interchangeable Milling machine, allowing customers to simply investing in only one machine with 2 heads for 3 different uses: Fitz Mill, Sieving Granulator and Sizing.

Fitz Mill head with Bar rotor function.

Inline Fitz Mill is integrated with Lifting system to suck / discharge powder from the Fluid bed.

Fitz Mill control functions are integrated on the Lifting system panel.

Feeding powder flow is controlled by V-Dosing valve.

Parts can be easily disassembled for cleaning and maintenance.

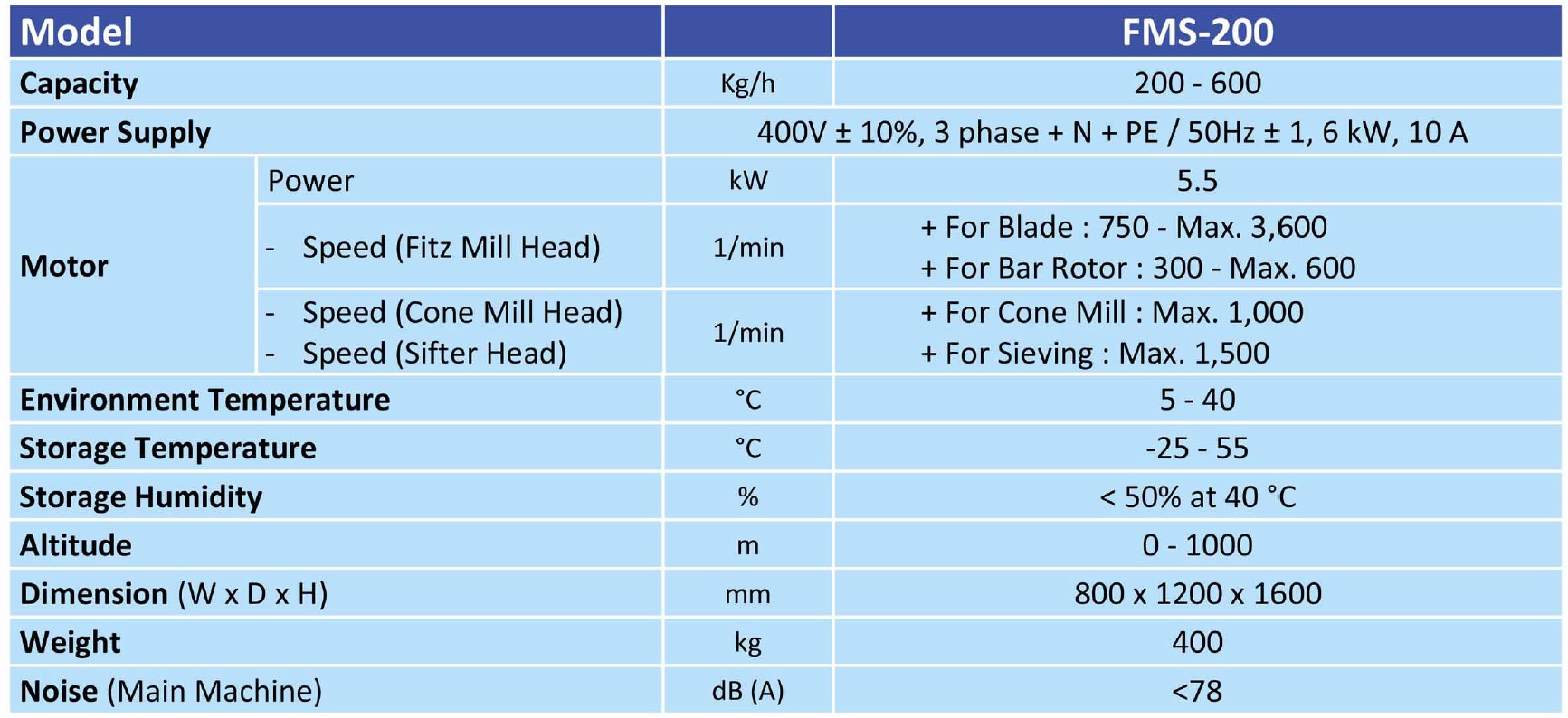

TECHNICAL SPECIFICAITONS: