EXTRUDING PELLETIZER, MODEL: SExP series

Capacity: Up to 100kg/hr

The Extruding Pelletizer is used to make pellets by extruding method from wet powder masses of Φ0.8-3.0mm depending on the die plate and composed powder.

In comparison to tablets, pellets have unique characteristics that make them more and more popular in solid form design. For instance, larger surface area allows binder solution to be distributed more evenly, thus make it become important attribute to drug properties, especially when immediate release is needed. Furthermore, uniform size of pellets enables uniformity from batch to batch and allows developing different dosage strengths without formulation changes.

The machine is a "3 in 1" system which includes Dosing, Extruding and Spheronization process. It is controlled automatically, independently & continuously.

Compact, occupying less space and machine can be moved easily thanks to 4 locking wheels.

Main units including: Dosing & Supply unit; Extruding Unit; Pelletizer & Spheronizer Unit; and Discharge Unit.

Full controlled by Siemens PLC and Touch Screen.

Easy and fast changeover. Parts can be easily disassembled for cleaning and maintenance.

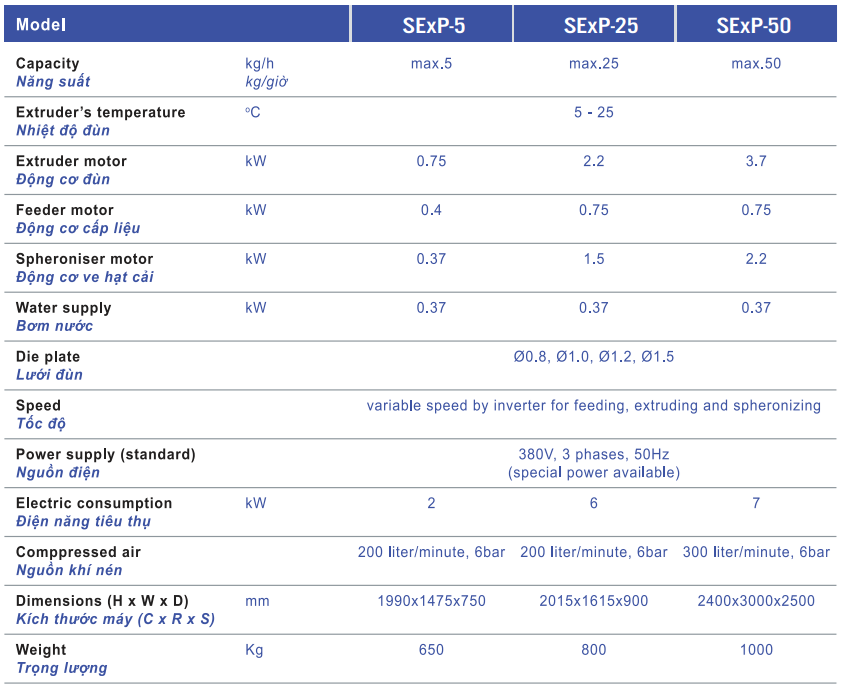

TECHNICAL SPECIFICAITONS: