In pharmaceutical manufacturing, precision and efficiency are paramount. STV Machine understands the importance of selecting the right equipment and techniques to meet these stringent standards. In this discussion, we highlight the crucial role of granulation methods and the significance of choosing the right technology in pharmaceutical equipment manufacturing.

GRANULATION METHODS IN PHARMACEUTICAL MANUFACTURING:

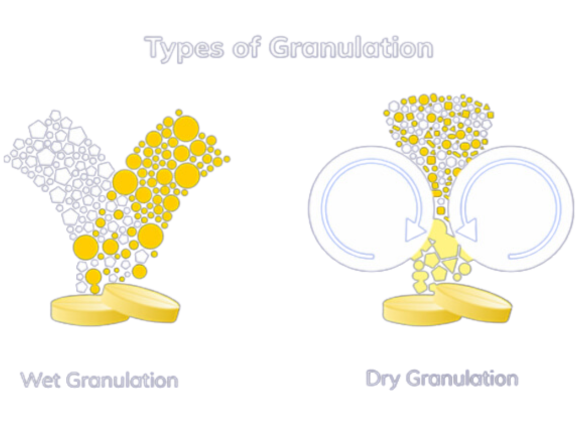

Granulation is a fundamental process in pharmaceutical manufacturing, and it comes in two main categories: Wet Granulation and Dry Granulation. Each of these methods has its own unique advantages and challenges, selecting the right one are paramount to ensuring product quality.

Wet Granulation:

Wet granulation is a method that involves the addition of a liquid binding phase to a powder bed. This process allows for the uniform distribution of Active Pharmaceutical Ingredients (API), resulting in better content uniformity, improved flow ability, and minimized tableting deficiencies. It is highly effective in enhancing the dissolution rate of poorly soluble drugs. However, wet granulation can be complex, time-consuming, and requires specific equipment.

STV Machine has made a deliberate choice to optimize wet granulation using state-of-the-art granulator machine. This approach ensures that we consistently produce the highest quality granules, meeting the stringent standards of the pharmaceutical industry.

Our processes for agglomeration and granulation have the purpose of shaping powder solids. The goal of these technologies is to make product handling easier and to enhance the properties of the starting material for dosage or further processing.

Depending on the starting substance, area of application and target parameters to be defined, various methods can be selected. In selecting the optimum process technology, production-specific aspects, such as processing time or use of resources should be considered in addition to the product properties.

Including:

- High Shear Mixer & Granulator, Model: HMG series

- Dryer, Granulator & Coater, Model: SDGC series

- Lifting Device with online cone mill, Model: LT(R) series

Dry Granulation:

Dry granulation is a cost-effective method that doesn’t involve the use of liquid binders or heat for drying. It is faster than wet granulation, ideal for hydro-sensitive and thermolabile APIs, and requires less space. Dry granulation is the preferred choice when direct compression is not applicable. However, it necessitates specialized heavy-duty tablet presses and may not provide uniform color distribution in the final product. Dust generation during the process is also a consideration compared to wet granulation.

Including:

- Roller Compactor, Model: RCS series

FINAL MIXING, BLENDER

STV Machine blending system is based on the principle of free-fall mixing (blending in a container) ; Pyramid type or V type for free-flowing powders and granulates.

Final mixing is a very important step in oral solid dosage pharmaceutical industry as a medicine is manufactured by mixing a number of drugs and chemicals.

The correct choice of a blender is very important for ease of operation, maintenance and cleaning without compromising the quality of product.

The inclination of the blender to the rotary axis - whether interchangeable containers or a firmly-clamped blending container - ensure highly efficient blending or homogenization in a very short time, depending upon the products. One need not install baffles (blending elements) in the head region of the blender container. Thus one blends in a closed system.

STV provides different types of Blenders to suit all pharmaceutical industrial environments and to accommodate different type of containers and Intermediate Bulk Containers:

- IBC Lift Blender, Model: LB series

- Pyramid Mixer, Model: P series

- V Blender, Model: V series