Tablet coating machines are mechanical devices designed to perform a simple process of applying a thin layer of coating material to the surface of the tablets. They deliver a bunch of benefits by placing a coating solution around the solid oral dosage form.

A tablet is typically formulated with one or more active pharmaceutical ingredients (APIs). The properties of many APIs are highly sensitive to the environment, so they need to be protected by a film of coating against external influences.

Typically, the tablet coating equipment performs a process that includes the following 7 steps:

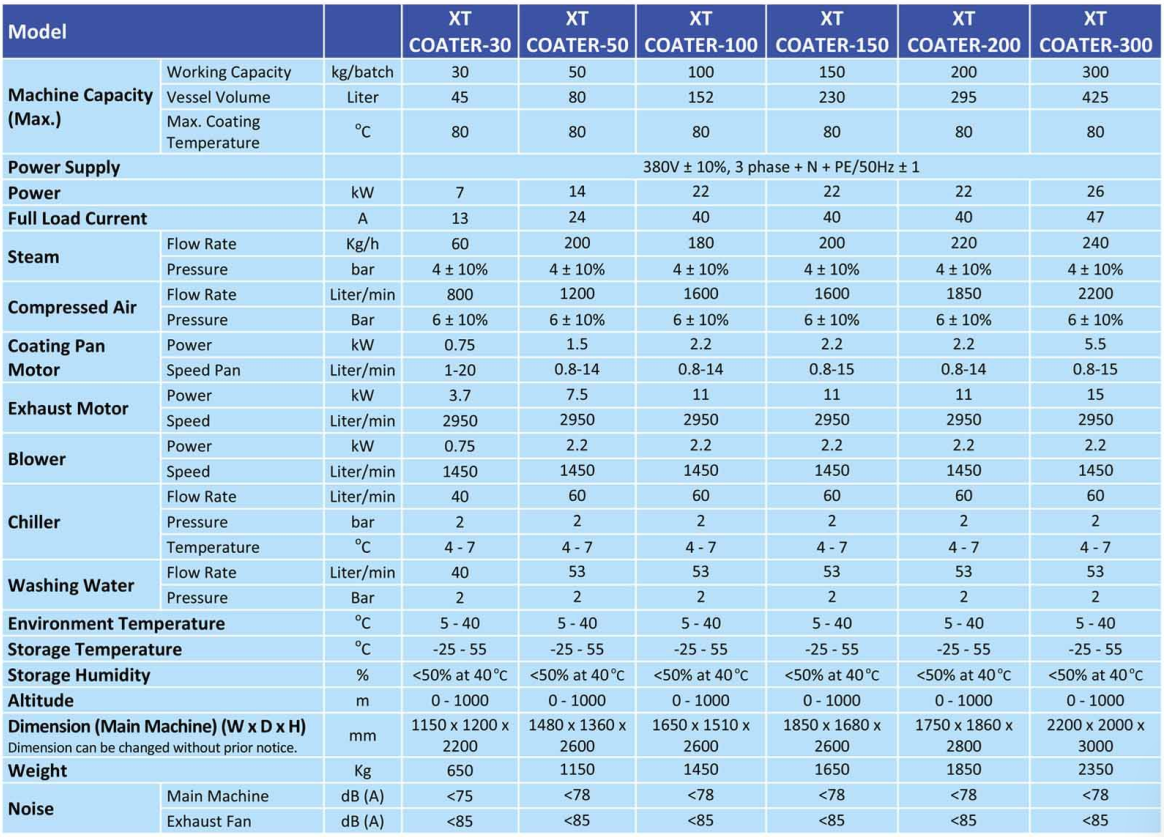

STV Coating machine is designed with various output capacity ranging from 5 kg per batch or more. By using advanced coating technology with fully perforated pan, air exchange efficiency is improved thus it reduces machine working time significantly while ensures coating uniformity for products.

Machine is available for both film coating and sugar coating, available for time-release tablet.

The coating system is designed for free-standing or through-the-wall. The technical area behind the room, gives minimum space requirement, fewer external surfaces to clean, all essential components are accessible from technical zone for maintenance and calibration.